-

What is Shot Peening?

What is shot peening?

Shot peening is a cold work, surface modification process aimed to improve the fatigue life of metal components through inducing compressive residual stresses. It is used when components experience metal failure due to high-cycle operating conditions.

Shot peening is commonly seen in the aerospace, automotive, heavy machinery, and power generation industries.

Why is Shot Peening so Important?

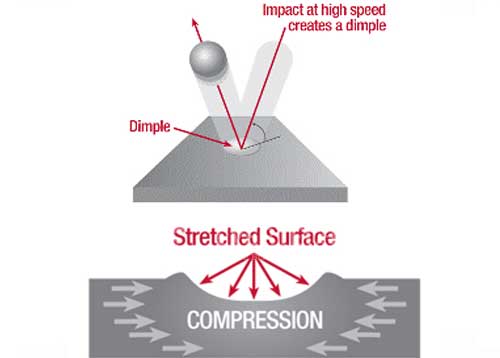

Shot peening has become a critical process in many industries due to its ability to improve metal fatigue properties and extend the life of critical components that could potentially fail. Metal fatigue occurs when cyclic loading and the associated tensile stress cause a crack to start in a highly stressed area. Shot peening is able to mitigate this by imparting a high magnitude, residual compressive stress at the surface in the potential failure area.

The shot peening compressive stress is opposite the applied tensile stress that causes a crack to start. Parts that have been shot peened are able to survive 3-10 times longer due to the surface being placed in a residual compressive state.

How Shot Peening is Applied?

Controlled shot peening is a cold working process which uses spherical media known as shot. Each piece of shot hits the surface and creates an indentation where the surface yields and is restrained by the substrate material. This creates a beneficial compressive residual stress which makes the surface resistant crack initiation and propagation. Prior manufacturing tensile stresses are converted to residual compressive stress

What has to be taken into consideration during shot peening?

There is a risk that a weakening of the component can be caused by an incorrect process (for example if the pressure is too high, or the distance between the work piece and the turbine is too narrow). A shortened and/or reduced fatigue and bending strength of the work piece could be the consequences.

In order to prevent this, different test procedures have been introduced since the development of the shot peening (approx. in 1935), as for example Almen intensity measurements, control of coverage rates or peenscan (a luminous paint which becomes visible under ultraviolet light). They were proven to be effective when properly used.

A reliable process control is important for shot peening in order to achieve the positive characteristics of the residual compressive stress and reproducible quality. During the Almen intensity measurement, today’s common method to control the blasting process, abrasive is shot on a small plate made of hardened steel (Almen strip). Based on the curve of the strip, we can draw conclusions about the blasting process.

Common types of shot media include

-Cast Steel Shot

-Glass Bead Shot

-Ceramic Bead Shot

-Cut Wire Shot

Shot peening applications

-Blisks

-Drill bits

-Rotary piston

-Chassis

-Springs

-Universal joints for drive shafts

-Hooks

-Bevel gear wheels

-Connecting rods

-Racing car transmission parts

-Spiral springs

-Stabilizers

-Masonry drills

-Synchronizer hubs

-Cup springs

-Crown gears

-Torsion profiles

-Gear parts

-Waves

-Wave springs

-Gears