Shot Blasting Machine

What is shot blasting?

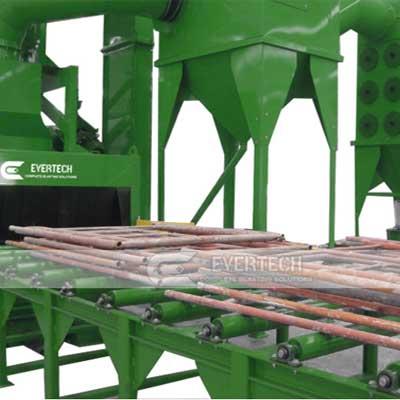

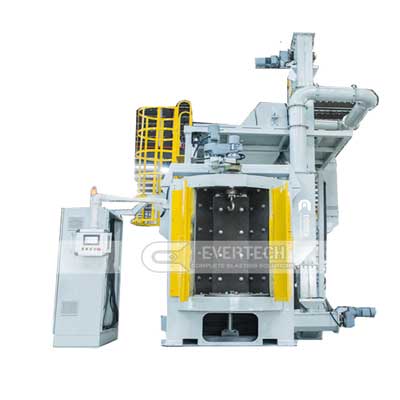

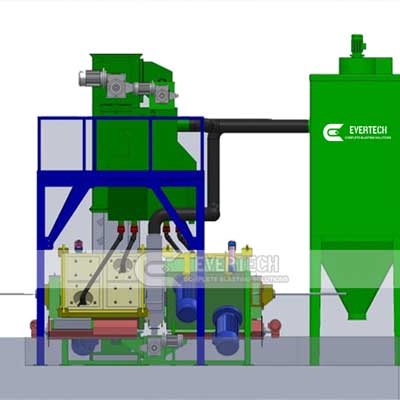

Shot blasting is a mechanical surface treatment process. It uses the centrifugal force of the blast turbines of the shot blasting machine during high-speed rotation to project the steel shot at a high speed to the surface of the metal steel, causing collision and blow plays the role of grinding, removing rust and other impurities on the metal surface, and the metal surface produces a certain degree of roughness. Commonly used shot blasting machine types include tumble belt shot blasting, roller conveyor shot blasting machine, hanger shot blasting machine, floor shot blaster, overhead rail shot blasting machine etc.

The shot blasting process is a closed operation, which will avoid the situation of dust flying and polluting the air. This shot blasting process is almost used in most fields of machinery, such as shipbuilding, auto parts, aircraft parts, guns Industries such as tank surface, bridge, steel structure, glass, steel plate profile, pipe inner and outer wall anti-corrosion and even road surface.

According to your different blasting materials and blasting effect requirements, we also provide customized production of shot blasting machine. Whether it is the machine parts selection or machine processing size, we are committed to satisfying your diverse processing needs with the highest price/performance ratio. With an annual export volume of over 200 units, the shot blasting machine from Evertech is definitely the first choice for your blasting industry.

Why to choose our shot blasting machine?

-Customized production can save you 30% of additional procurement costs.

-International top brand accessories to ensure your higher productivity and increase profit margin by 40%.

-Professional product and operational training, reducing operating error rate by 80%.

-Perfect after-sales service can help you avoid any worries in the use of the machine.

Safe operation

1. It is forbidden to operate the shot blasting machine without protective equipment.

2. When adding or recovering steel shot, the dust removal fan, horizontal screw, bucket elevator and vertical screw must be turned on first.

3. Periodically turn on the dust removal pulse back blow to remove dust. Extend the dust-removing pulse back-blowing time for 30 minutes after shutdown.

4. It is forbidden to continuously turn on each control switch in a short interval. Prevent the instrument from being burnt due to excessive current.

5. Regularly check the wear and tear of various wear parts, and regularly clean up the garbage at the filter and steel shot supply valve.

6. During the hoisting process, do not put your body under the component, try to avoid the direction of the component falling, and pay attention to the safety of hoisting.

7. Pay attention to slips and falls