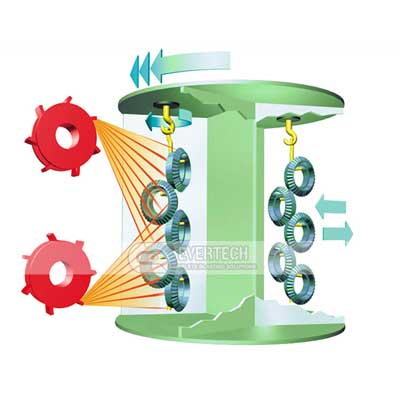

Shot Peening Machine

What is Shot Peening?

Process of shot peening involves accelerating a steel shot or other hard media (metal, ceramics, glass) toward a component’s metal surface at high velocities. The impact of the media with the metal surface causes a plastic deformation which changes the mechanical properties of the surface. The mechanical change of the metal surface produces compressive residual stresses and crack initiation is prevented or slowed down.

-Shot Peening

Used to induce residual compressive stress in the surface of components that are prone to cyclic and repetitive loads, the process also reduces stress corrosion cracking.

-Shot Peen Forming

This process compresses and extends the superficial layer of the component causing it to bow. Typical applications include the formation of skins, wing flaps, access panels, and sections of fuselage.

-Correction Of Distortion

(The reverse of shot peen forming) Shot peening is used to stretch and compress a localised area to achieve perfect flatness after a part has been distorted by heat or machining. Complex structural parts, ribs and spars typically undergo this process.

Shot Peening Media Used

Media used for the shot peening include: steel, ceramics and glass.

Ceramic Peening Services – Used to improve the wear properties of gears, ceramic and virgin media is used to blast the gear. The resulting dimples retain beneficial oils and eliminate geartooth pitting.

Metal Deburring Services – Our metal deburring services offer different types of media to remove burrs and other imperfections from the part.

Glass Bead Peening Services – Using glass beads, this process produces a clean, bright satin finish to the metal part.

Steel Shot Peening Services – Steel shot peening is used to deburr and clean metal parts while improving the fatigue life of the part.

Shot Peening Application

Our automated equipment is custom built to fit your requirements and application, from shot peening gears and turbine/jet engine blades to drills and engine blocks:

-Gears

-Camshafts

-Shafts

-Turbine Blades

-Connecting Rods

-Engine Blocks