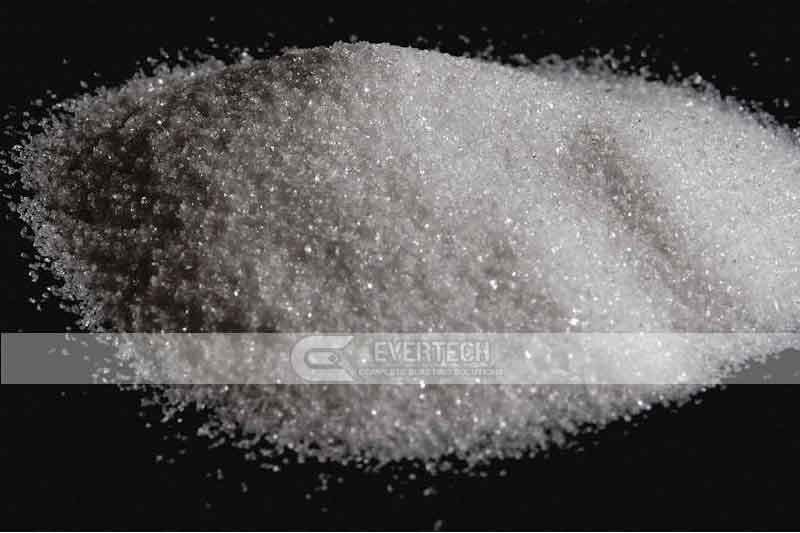

Aluminum Oxide Blast Media

Position: Home > Aluminum Oxide Blast Media > Aluminum Oxide Blast MediaAluminum Oxide Blast Media

Aluminum oxide is one of the more aggressive blasting materials that can offer fast results and superior strength. Its angular but lightweight design allows it to create deep etching without adding su

| Model | Blast Media |

| Price | Negotiation |

| Rating |  4.0 /5 based on 28 ratings and reviews 4.0 /5 based on 28 ratings and reviews |

| Operation Method | Automatic/Manual |

| Brand name | Evertech |

| Place of Origin | Qingdao, China |

| Certification | CE, ISO, UL |

| Process | Continuous/Batch |

| Industry | Light/Medium |

| Delivery Time | Within 4 weeks |