The machine

Whether the subject is degreasing, heat treatment, vibratory surface finishing or shot blasting, etc., there has always been a demand for continuous operation. Batch operation usually requires complicated and costly handling systems for collecting parts and consolidating them into batches, loading them into the processing machine and to integrate them into the next manufacturing step. Also, batch operation frequently causes parts impingement resulting in high scrap rates.

On the other hand, continuous operation facilitates parts flow and can easily be integrated into automatic manufacturing processes saving costly handling systems and minimizing scrap rates.

Applications

-Blasting and sand removal

-Ferrous and non-ferrous pieces including manifolds, cylinder sleeves, connecting rods, cams & pistons and pipe fittings

-Hot work pieces up to 250F (121C)

-Heavy duty foundry work piece

-High cleaning capacity, short blasting times

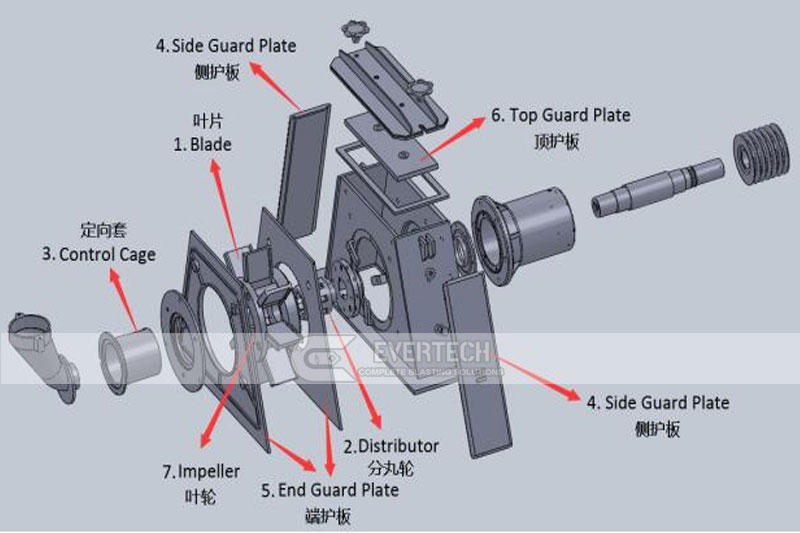

-Careful arrangement of blast wheels on the machine results in ---optimum utilisation of the abrasive energy

-Full exposure of all workpiece surfaces to the blast stream

-Entirely automatic, continuous production flow

-Blast cleaning performance is maintained at a consistently high level, regardless of fluctuations in production rates

-Easy maintenance set up

-Integration into existing production lines

-Leading technology, outstanding experience

-Adaptable inlet, outlet and blastroom set up to meet different workpiece configurations

-Adaptable to treat tumble-proof fragile castings

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews