Description

This kind of shot blasting machine are the most cost-effective solutions, it is suitable for the company which provide blast cleaning services for cylinders, and the productivity for this kind of shot blasting machine is about 50 to 150 pieces per shift at most.

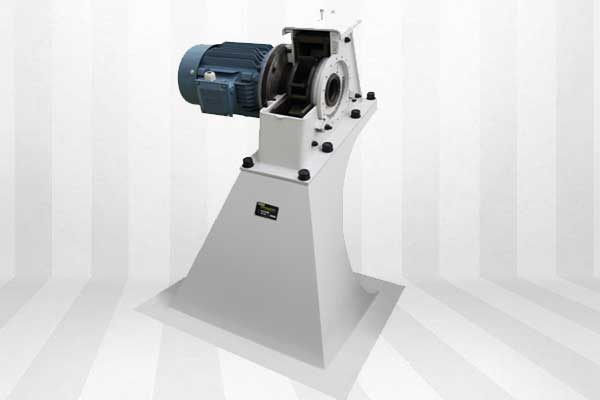

Spinner hanger blasting machine is designed to process heavy and complex shaped work pieces, which are manufactured in smaller or medium series. Work pieces can weight from 1 kg to 50,000 kg or more. Basic spinner hanger is ideal for less demanding users, as it has predefined characteristics and limited options, but despite all these achieves high production quality.

Work pieces are mounted individually or in a cluster on a hook and transported in the machine. Transport system is I, Y or circular closed loop conveyor. Work pieces are blasted in a jet of abrasive, which provides efficient treatment of the surface. Housing of spinner hanger blasting machine is protected by wear-resistant manganese steel or entirely made of manganese steel and is additionaly protected on the most exposed areas. High efficient blasting is achieved by simultaneous rotating and oscillating movement of the hook and by the automatic and continuous abrasive handling and reclamation system for continued returning and cleaning of the shot blasting media, along with efficient blasting wheels made from wear-resistant materials.

Operation

-Work pieces are placed in work piece holders or are suspended directly from the running gear’s rotating hook. The work pieces are then pushed into position in front of the blasting machine. An automatic feed mechanism then advances the work pieces to the first blasting position.

-After the blasting program begins, the machine door is automatically closed and electro-pneumatically locked. As the work pieces rotate, they are blasted at three different blasting stations according to the pre-set blasting times.

-The blasting abrasive is continuously cleaned, recirculated and reused. An abrasive metering device feeds the cleaned abrasive from the abrasive storage bunker to the high-performance turbines.

-Upon completion of the blasting cycle and after the turbines have come to a complete stop, the machine door opens automatically and the suspended work pieces return to their initial position.

-A fan unit creates the partial vacuum necessary to maintain dust-free operation of the blasting unit. Extracted air is cleaned in a special filter unit.

Features and benefits

-Economical abrasive consumption, reliable cleaning with dust collection feature.

-High sand separation capacity and can combined magnetic and air-wash separation system.

-Low maintenance due to its maintenance-friendly design

-Easy access to maintenance areas and easily replaceable its part.

-Multiple machine sizes and variations available.

Applications

-Blast cleaning welded steel fabrications

-Deburring and homogenising diecast parts

-Peening dynamically stressed components

-Removal of mill and forge scale as well as rust

-Removal of burrs and scales

-Increase of surface roughness

-Shot peening to increase fatigue strength

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews