Glass Bead Media

Position: Home > Glass Bead Media > Glass Bead MediaGlass Bead Media

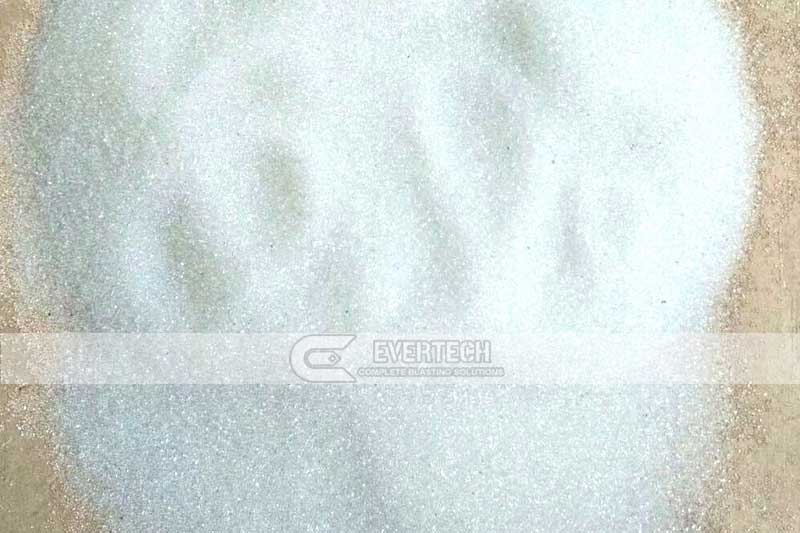

Glass bead blasting is a versatile approach to abrasive blasting that offers an attractive satin finish and works for a variety of purposes. It uses lead-free soda lime-type glass in rounded ball shap

| Model | Blast Media |

| Price | Negotiation |

| Rating |  4.0 /5 based on 28 ratings and reviews 4.0 /5 based on 28 ratings and reviews |

| Operation Method | Automatic/Manual |

| Brand name | Evertech |

| Place of Origin | Qingdao, China |

| Certification | CE, ISO, UL |

| Process | Continuous/Batch |

| Industry | Medium/Heavy |

| Delivery Time | Within 4 weeks |