The machine

The flexibility of overhead monorail transport offers a variety of possibilities for optimum material flow and contributes to a considerable reduction of finishing costs. Monorail systems solve for blast cleaning and handling problems, fitting seamlessly into a production line. The transport hanger is loaded with components outside the machine and then moves into the shot blast cabin where all surfaces of the workpieces are treated in one passage.

Features and benefits

-Sturdy, welded housing structure in manganese steel reinforced with profiles

-Additional bolted and suspended manganese wear plates in the hot area

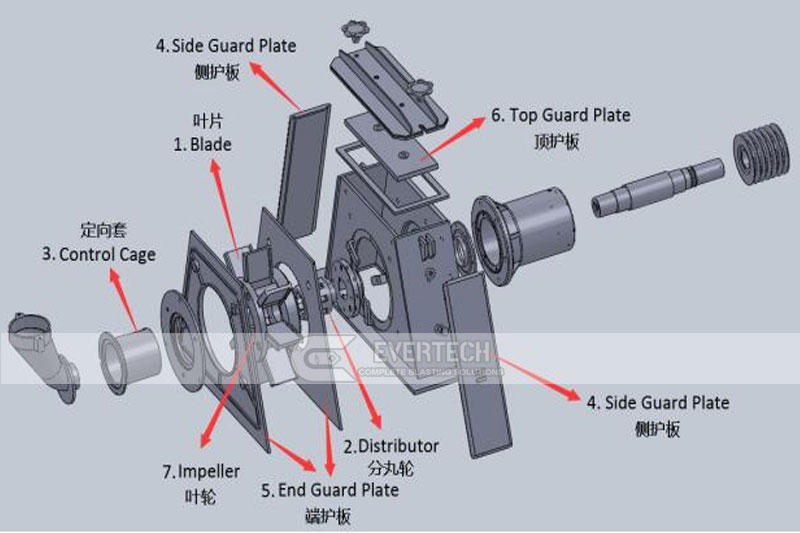

-Heavy-duty, direct drive blast wheels

-Lower vibrating conveyor to separate gating or feeder parts and burrs from abrasive media

-Lower rotating scalping drum for light duty application

-Abrasive cleaning and separation using combined magnetic / air-wash separators

-Overhead monorail in a variety of configurations

Machine parts (including front wall, floor and roof) directly exposed to the blast stream and subject to increased wear are protected by replaceable manganese steel liners.

Example of treated products

-Aluminium die-castings and its alloys

-Casting of ferrous and non-ferrous metals (with application of special devices such as magnetic separators, vibrating screens, etc.)

-Structural steel works

-Gears, for heat treatment

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews