Rotary Drum Shot Blasting Machine Application

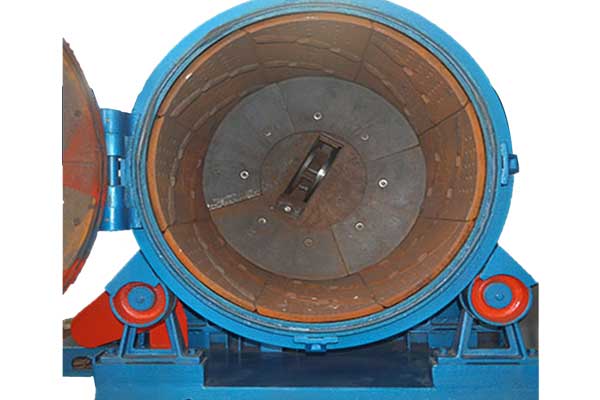

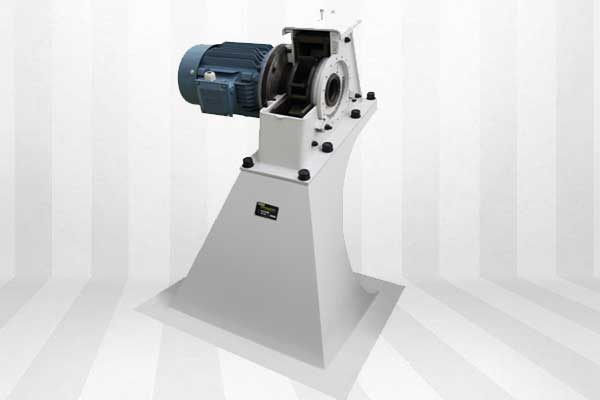

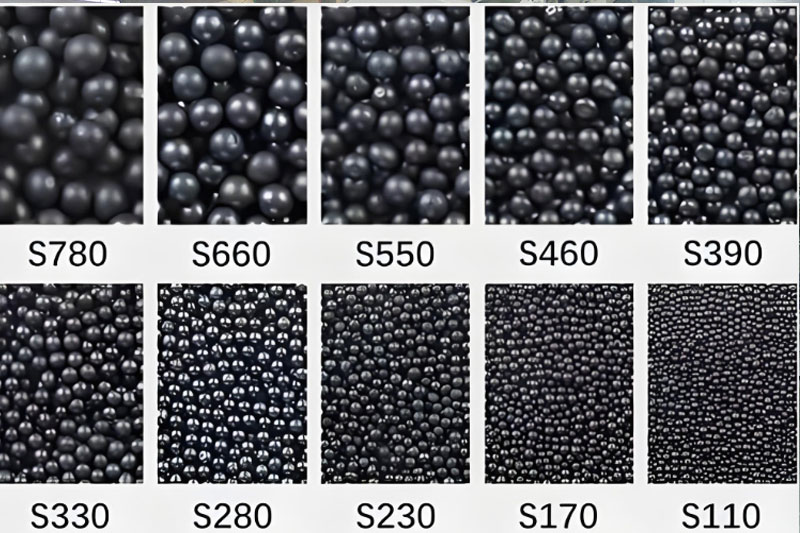

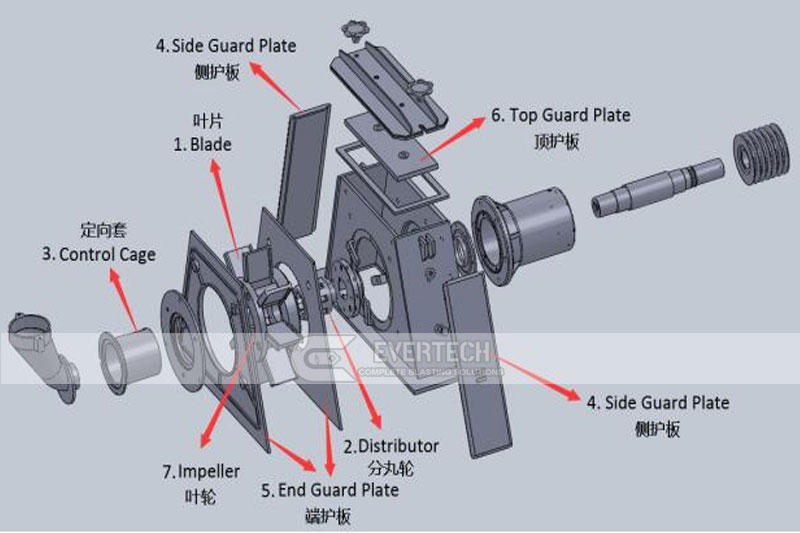

The high-speed blast wheel throws the abrasive to the continuous tumbling castings or forgings in barrel, to remove the greensand or scales on the surface. It cleans evenly and its productivity is high, so it is suitable for cleaning the small work pieces whose weight are under 30KG in medium or small-scale casting or forging workshops.

As the machine has individual dust-collecting device, the installation spot is not limited by the ventilation pipelines in workshops. The cleaning condition is fine. The machine is equipped with auto-stop device, so it is convenient to operate.

Rotary Drum Shot Blasting Machine Working process

Put the cleaning work piece into the barrel and close the end-cover, and then adjust the cleaning time. First, move the semi-nut needle to the desired position, and then start the machine in turn.

After the barrel rotating, the helical ribs on the protecting board tumble the castings continuously, to make each surface cleaned evenly. Through the hole , the abrasive flows into the middle-wall, then through the screw belt conveying to the box-shaped frame , via elevator carrying to the top of the separator. Screen such big core-sand and burrs, etc, the small sand, dust and abrasive are carried away by the airflow. The integrity shot flows into the blast wheels for continuous usage.

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews