Hanger shot blasting machine blast cleaning wheel rims

Spinner hanger blasting machine is designed to process heavy and complex shaped work pieces, which are manufactured in smaller or medium series. Work pieces can weight from 1 kg to 50,000 kg or more. Basic spinner hanger is ideal for less demanding users, as it has predefined characteristics and limited options, but despite all these achieves high production quality.

Continuous overhead rail shot blasting machine

If you need very big cleaning efficiency, you can choose this type machine.

The flexibility of overhead monorail transport offers a variety of possibilities for optimum material flow and contributes to a considerable reduction of finishing costs. Monorail systems solve for blast cleaning and handling problems, fitting seamlessly into a production line. The transport hanger is loaded with components outside the machine and then moves into the shot blast cabin where all surfaces of the workpieces are treated in one passage.

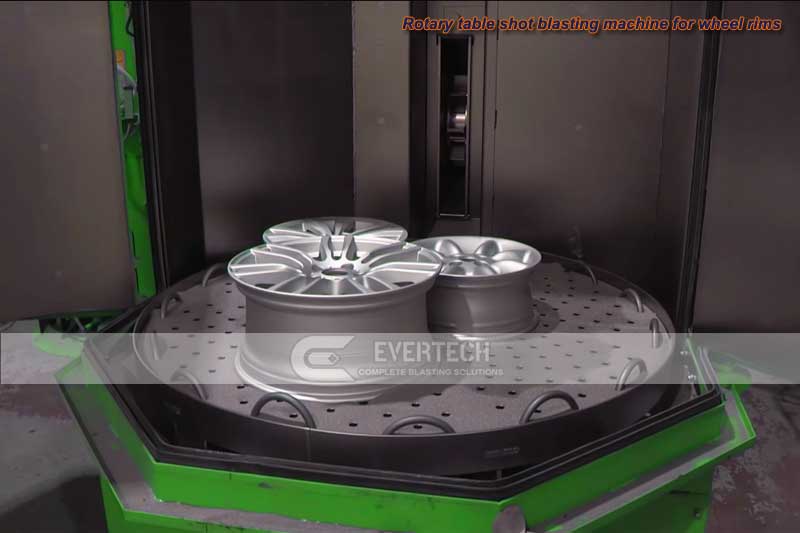

Rotary table shot blasting machine blast cleaning wheel and rims

Table Blast models are the ideal choice for a wide variety of parts that are not suitable for tumbling due to size and shape. Parts are rotated on the table and are cleaned by exposure to the abrasive blast of our blast wheel(s). Most applications are covered by the standard offering, but can also be fitted with a rotary scalping drum, auxiliary abrasive hoppers, peening packages and various horse power options. We also offers custom sizes and wheel configurations to accommodate specific application requirements.

Roller conveyor shot blasting machine blast cleaning wheel rims

Roller conveyor shot blasting machine is a good way to blast cleaning wheel rims. they can be easily integrated into the existing production line, have high production capacity. For blast cleaning wheel rims with through feed widths from 600mm to 2000mm, suitable for cleaning wheels of various sizes

Wire mesh conveyor shot blasting machine blast cleaning Wheel rims

Wire mesh belt shot blasting machine excellent for all-round, complete and continuous blasting treatment of flat as well as voluminous and very complex components.

Wire Mesh Belt shot blast systems are designed to provide a high throughput for a variety of product sizes and shapes. This proven continuous in-line shot blast cleaning system is available in standard and custom Designs. This system is ideal for deburring, general cleaning, descaling and deflashing and is equipped with 2- 16 shot blast wheels, processing widths ranging from 400 mm to 1600 mm, depending on your cleaning and production requirements, suitable for high production capacity for cleaning wheel rims and the working process is continuous.

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews