Successful installation and commissioning of hook type shot blasting machine in Colombia

The hook type shot blasting machine is disassembled into several parts after installation and debugging in the production plant, and then transported to the user's application site for installation.

Successful installation and commissioning of hook type shot blasting machine in Colombia

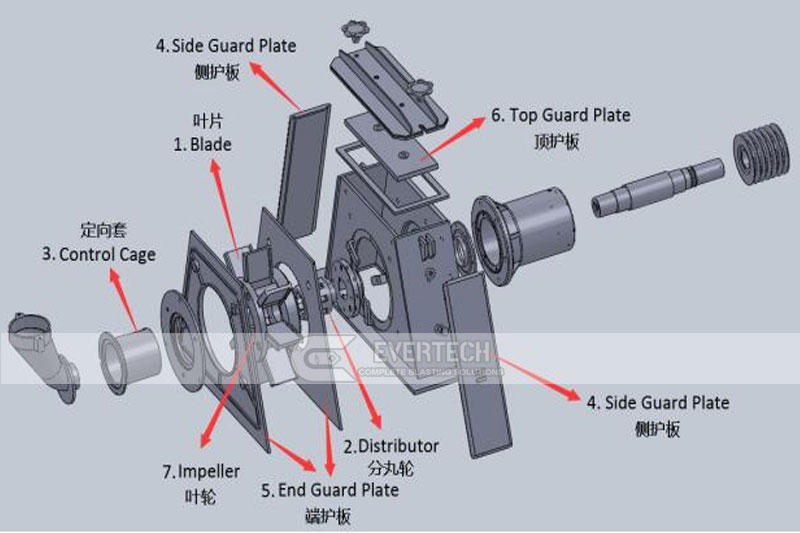

1. Blast turbines

The blast turbines have been installed on the blasting chamber before leaving the factory, and the problems to be debugged should be paid attention to before use. Check whether the fixed position of the blade, the pellet wheel, the directional sleeve and the guard plate is accurate and firm, and jog the power to check whether the rotation direction is correct. Then adjust the orientation of the opening of the directional sleeve. In theory, the angle between the front edge of the directional opening and the front edge of the blade throwing orientation is about 90°. After fixing the orientation of the orientation sleeve, the orientation of the ejection belt can be detected. Place a steel plate or a wooden board facing the exit of the shot blasting machine at the position where the workpiece is hung, start the shot blasting machine, put a few (2-5kg) projectiles into the shot feed pipe, and then stop the machine to check whether the impacted position on the steel plate is suitable for the needs, such as Close the window of the partial adjustable directional sleeve downward, and vice versa until it stops properly. And write down the orientation of the directional sleeve as a basis for future replacement of the directional sleeve.

2. Elevator and screw conveyor

First carry out the no-load test to check whether the working direction of the lifting bucket and the screw blade is correct, then tighten the belt of the hoist to a moderate degree of tightness to avoid deviation, and then carry out the load test to check the working condition and transportation capacity. Noise and vibration, check and remove obstructions.

3. Separator

First check whether the gate movement is flexible, and then check that the orientation of the cooking plate is moderate. Then, when the hoist is debugged under load, there is continuous inflow of steel shot, and when the hopper is unloaded, check whether the steel shot flows out and falls in the form of a curtain.

Precautions

(1) According to the size and shape of the workpiece, a variety of suitable spreaders are produced. The spreaders exert the power of the projectile ejection belt separately, and at the same time reduce the impact and wear of the shot blasting room guard plate by the air shot.

(2) When the hook is driven into the indoor center, it must be in place, then close the door, press another stroke switch, and start the shot blasting machine to ensure the safety of operation and repair, and ensure that the ejection belt is fully utilized.

(3) Always check whether the projectile stream at the supply gate is full, and the projectile storage capacity is insufficient, and should be replenished in time.

(4) If it is found that the shot blasting machine vibrates too much and has abnormal noise, it should be stopped immediately to check whether the shot blasting machine blades have unbalanced wear or cracks, and the two symmetrical blades should be replaced in pairs.

If the angle of the blast turbine is inappropriate or incorrect when the hook type shot blasting machine is working, it will cause uneven shot blasting on the surface of the workpieces, and then cannot achieve the purpose of comprehensive and thorough cleaning, affecting the quality of shot blasting and Therefore, in the use of the hook type shot blasting machine, the angle of the shot blasting machine is required to be correct and appropriate to ensure the shot blasting quality of the hook type shot blasting machine.