Working principle

-The pipes inner wall sandblasting machine designed by Evertech has a large pipe diameter and a small steel pipe shot blasting machine with a diameter of less than 600mm.

-Steel pipe inner surface sandblasting machine adopts automatic sandblasting removing surface rust, use of compressed air through efficient sand blower ejected high-speed projectile flow shatter steel beam on the surface of the scale, rust layer and sundry, to obtain fine bright surface, improve the tensile and compressive strength, increase adhesion for the coating on the inner surface protection, achieve anticorrosive, protection tube, prolong the service life of steel pipe.The finish and roughness of the workpiece surface after cleaning conform to the relevant standard.

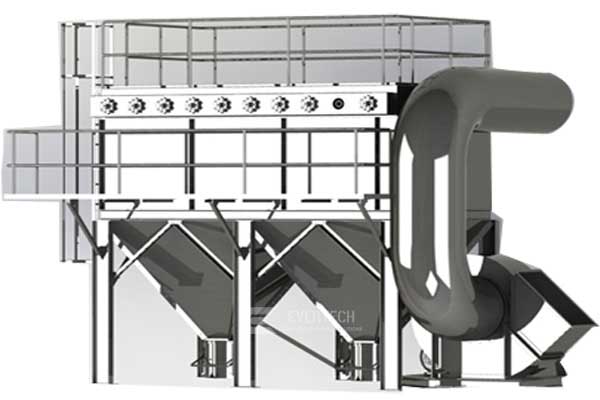

Structure and composition

The steel pipe inner wall blasting machine is mainly composed of front and rear movable auxiliary chambers, left and right inner wall hydraulic movable shot blasters, belt conveyor type projectile conveying mechanism, bottom belt conveyor, hoist, maintenance platform, separator, dust removal system, inner wall shot blaster It consists of walking mechanism, steel pipe unloading mechanism, hydraulic system and electric control system.

Process flow

Pneumatic loading - automatic pipe bracket rises - automatic pipe bracket in place down - steel pipe rotating bracket move to back seal chamber - front seal chamber moving - steel pipe rotation - dust colletcor on - abrasive recycle system on - sand blast cart moving - sand blast finished - sand blast cart exit c/w air blower - abrasive recycle system off - dust collector off - rotation off - unloading automatic.

Application

The sandblasting machine is suitable for continuous surface treatment on the inner surface of steel pipe before welding or painting. It is a special equipment for cleaning the inner wall of pipe. After shot peening treatment, a certain roughness of the smooth surface is obtained, increase the coating adhesion, improve the surface quality and anti-corrosion effect.

Contrast

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews