Pipes Shot Blasting Machine

Position: Home > Pipes Shot Blasting Machine > Pipes Inner Wall Shot Blasting MachinePipes Inner Wall Shot Blasting Machine

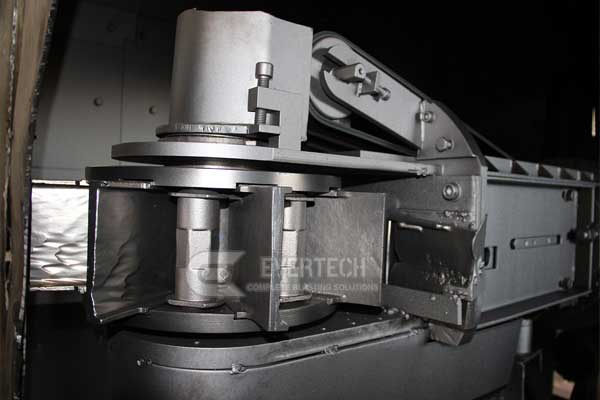

The ID of the pipe ranging from 600mm diameter to 2000mm diameter and Max length 12000mm, we design the loading mechanism as Inclined Rail Type. When the pipe reaches to the work position, the moveabl

| Model | Type ETNB |

| Price | Negotiation |

| Rating |  4.0 /5 based on 28 ratings and reviews 4.0 /5 based on 28 ratings and reviews |

| Operation Method | Automatic |

| Brand name | Evertech |

| Place of Origin | Qingdao, China |

| Certification | Qingdao, China |

| Process | Continuous |

| Industry | Medium/Heavy |

| Delivery Time | Within 12 weeks |