The Machine

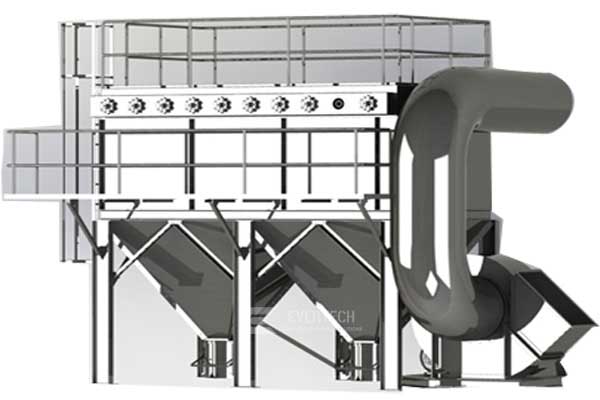

For the scaffolding cleaning shot blasting machine, our company designs two types of shot blasting machines to clean them. One, hanger type shot blasting machine. Another, roller conveyor shot blasting machine. There are advantages to both kinds of blasting machines. Hanger type shot blasting machine is suitable for short scaffolding, and it needs some time to load and unloading the scaffolding from the hanger. It needs to clean one group then unloading it, then clean the next group. It can not do blasting continuously.

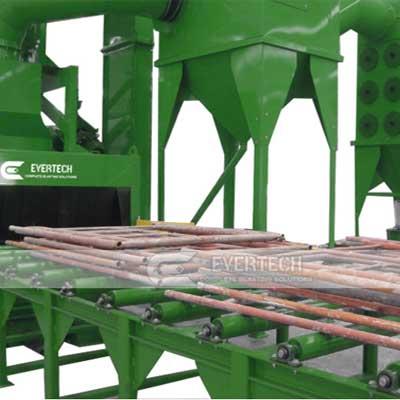

A Roller conveyor shot blasting machine is suitable for all kinds of scaffolding. It is very easy to loading and unloading the scaffolding, no need to stop working. And it can achieve blasting continuously.

Generally, the working efficiency of the scaffolding roller conveyor shot blasting machine is higher than the scaffolding hanger type shot blasting machine. I hope these two type of shot blasting machines can meet your needs.

Application of Scaffolding Cleaning Shot Blasting Machine

-Typically used in situations requiring the blasting of H beams, Angles and flats, steel plates, steel pipes, square tubes, box iron at a high rate.

-Improve corrosion protection to corrosion of machine and metal profile.

-Improve anti-fatigue performance and extend steel life

-Improve the steel surface craft performance

-It benefits the laying-off and precise blanking to NC cutting machine

-Because the steel is natural shape before processed, so it good to rust

-Removing and anti-rust paint spraying by auto-machine. Improve the cleaning efficiency

-Reduce labor intensity for cleaning.

-Alleviating environmental pollution

Features of Scaffolding Cleaning Shot Blasting Machine

-Blast wheels for outstanding speed without sacrificing coverage.

-Perfect for moving Steel device to the blast chamber by conveyor rolls

-wide range of machine types for different production rates and workpieces of different sizes

-High production rates, high blast cleaning performance

-Economical abrasive consumption. With 3 classes full flow film hammer style abrasive reclaim system. The abrasive media is cleaned and recycled, reducing disposal and minimizing abrasive costs.

-The number and power of the turbines are chosen according to the required production rate.

-PLC control system, stable quality, and easy to get help from local.

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews