Steel Plate Shot Blasting Machine Features and benefits

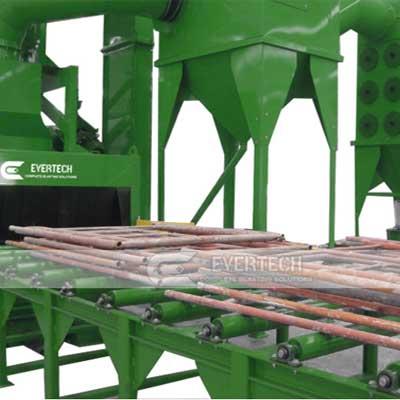

1. This machine has mainly been developed for the treatment of plates and profiles in the steel manufacturing and processing industry.

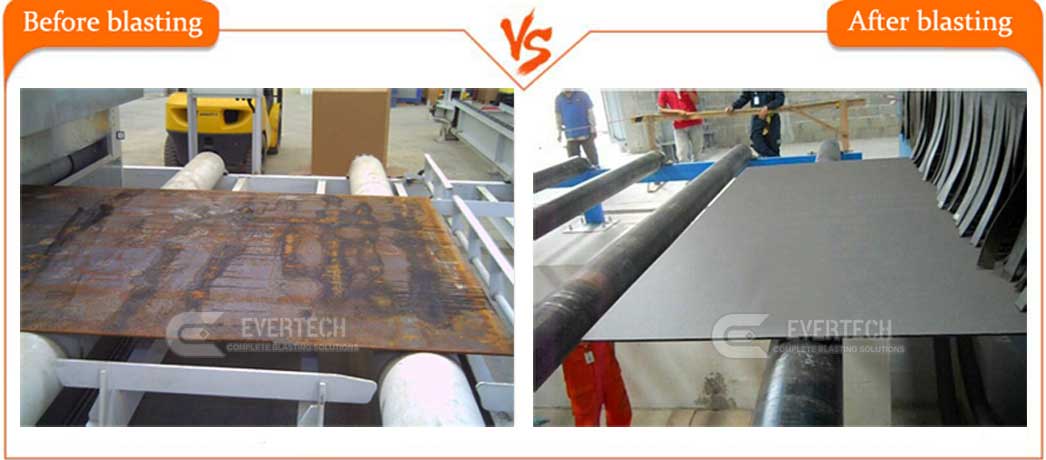

2. We offer our standard program of steel plate, profiles blast machines in processing widths ranging from 1000mm to 4300mm, rust removal grade can reach to Sa2.5-Sa3.0

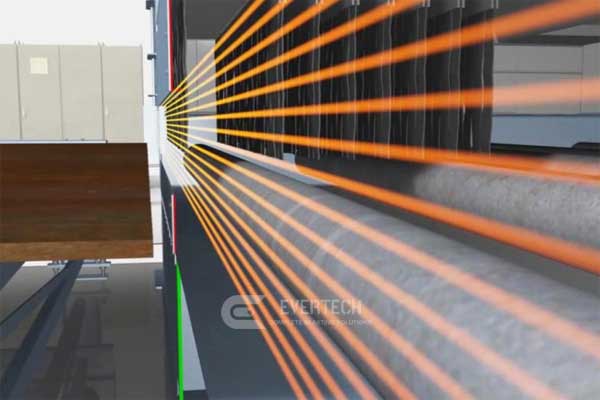

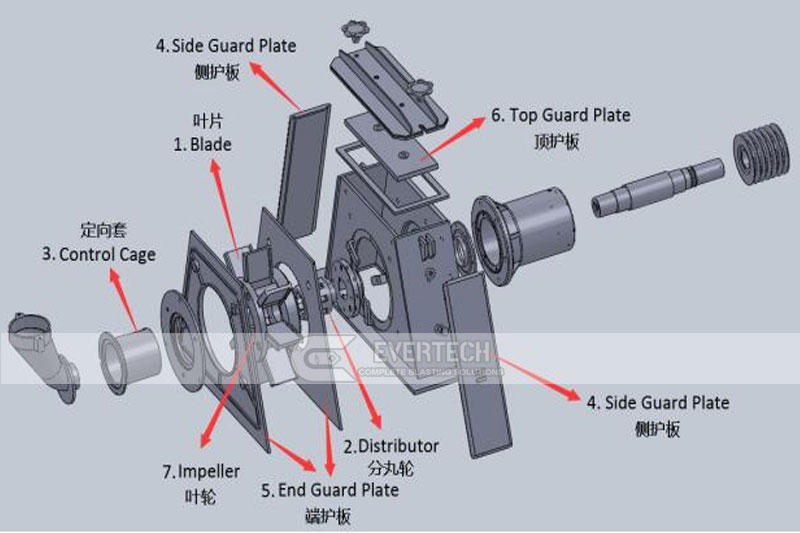

3. Demonstrates the highest performance variants of this machine type for blasting sheet metal and profiles

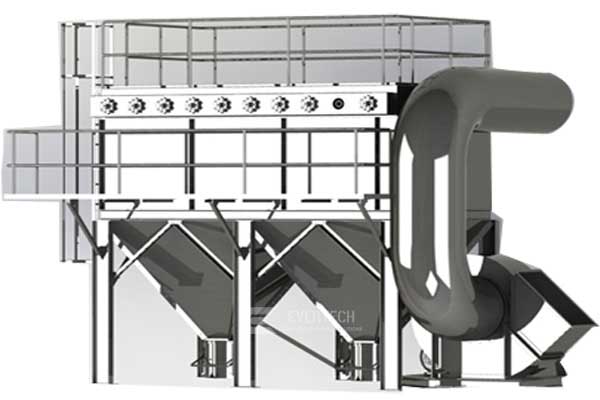

4. All inspection ports are easy to access and a maintenance platform is standard.

5. The heavy duty, variable speed chain driven internal roller conveyor is easily connected to extension input and output conveyors. Transfer speed is easily adjusted to achieve the desired surface finish.

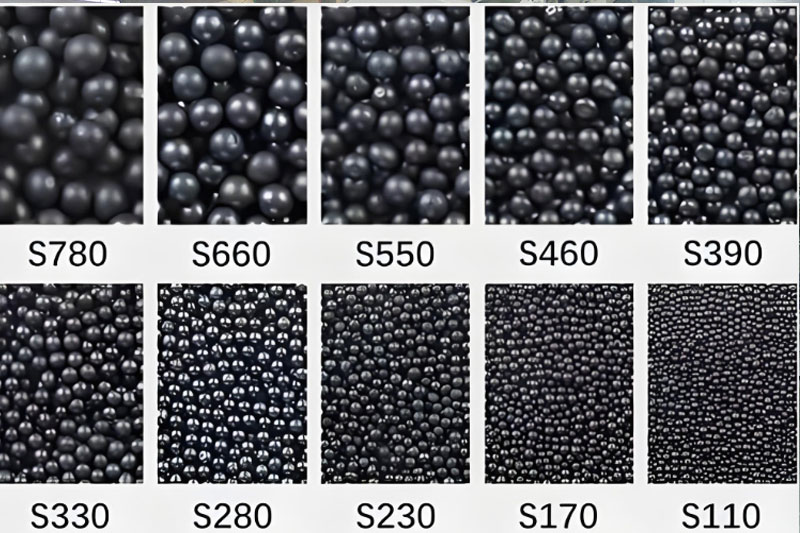

6. Automatic abrasive reclaim system with airwash abrasive separator for effective utilization of blast media

7. The simple maintenance requirements, the reduced abrasive consumption and reduced energy consumption all add up to a significant reduction in operating costs.

8. Particularly useful for integration into fully automatic production lines.

9. Evertech products include standard and custom systems to meet individual customer requirements.

Steel Plate Shot Blasting Machine Application

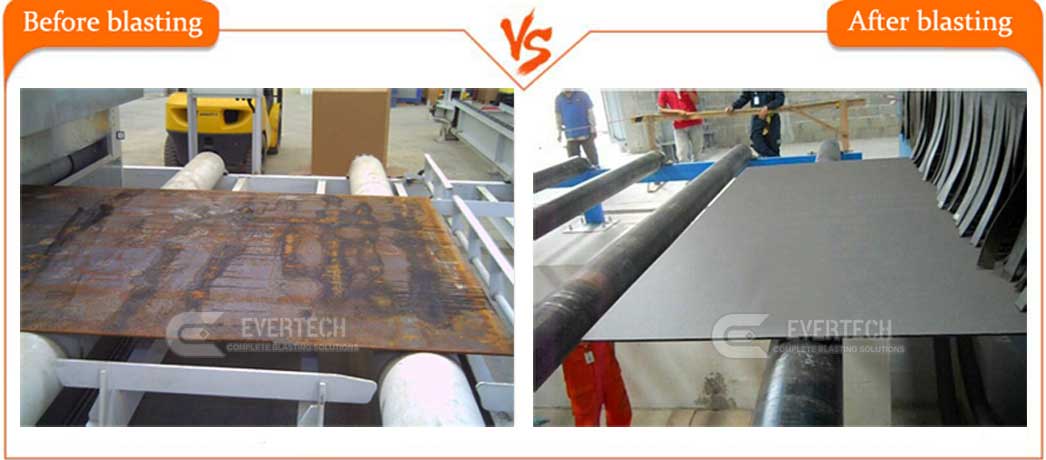

Descaling

Removal of oxide and welding rest

Preparation of the surface to the following treatment of paint

Preparation of the surface to the following machining

Steel Plate Blasting Contrast

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews