Pass Through - Roller Conveyor Type Shot Blasting Machine

Thanks to our customers in Australia for choosing our company and our machine. The customer mainly blast cleaning steel beams.

This pass through - roller conveyor type shot blasting machine is a stable and commonly used shot blasting machine, which can be used to clean H steel, steel plate, I-beam, angle steel, round steel, flat steel, steel pipe, steel structure, axle, frame, radiator and other workpieces. It can achieve the effect of removing burrs, rust, surface attachments, etc., while increasing the adhesion of the surface.

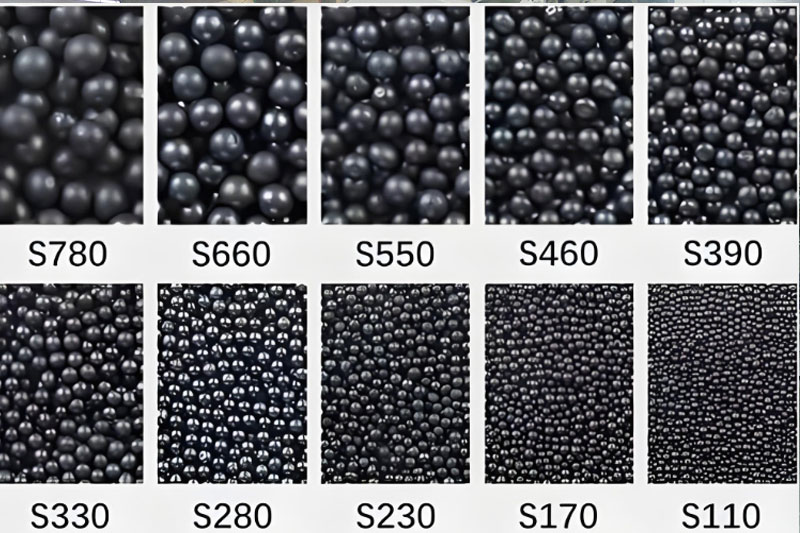

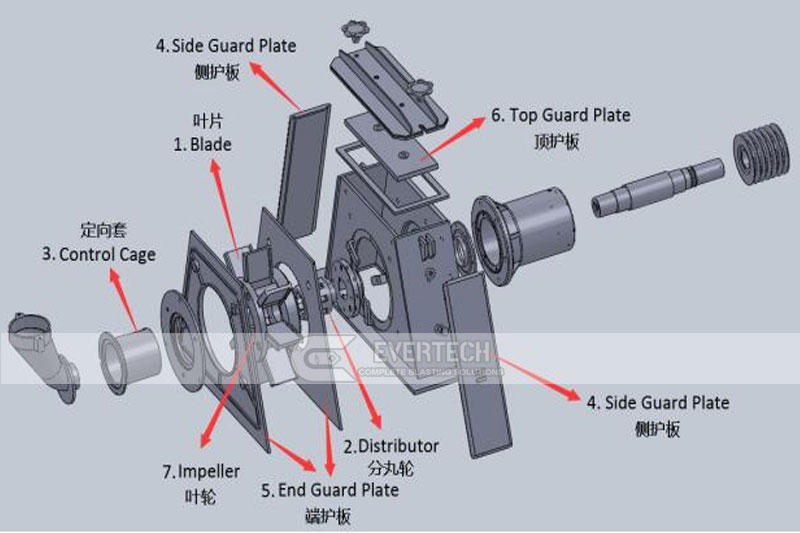

4 units 15 kw blast turbine, blast cleaning speed 0.5-6m/min(Frequency Control). Add high pressure blowing fan in the exit of the blasting machine, which will easy to remove the abrasive on the surface.

Blasting chamber manufactured in continuously welded Carbon Steel plate construction. The guard plate is secured to the cabinet walls with High Alloy steel cap nuts and are mounted in line with the abrasive blast stream. 4 layers of natural rubber protective curtain to prevent steel shot come out from blasting chamber.

We will pre-assemble the small beams shot blasting machine together at the factory and test the machine before delivery, for a non-standard machine that is tailored by customer detailed requirements, this is the most important thing during the installation.

Assemble a 60-ton circulation system, including longitudinal screw conveyor, crosswise screw conveyor, elevator and air wash system. Can effectively complete the separation, the steel shot can be use in the silo.

2-level dust collector system ensures that all dust generated during shot blasting can effectively enter the dust collector to meet environmental protection requirements. Dust collector with fully automatic continuous cleaning of the filter cartridges by means of compressed-air pulses which can be adjusted in their duration and frequency, extends the service time of the cartridge filter.

A mature Siemens PLC system controls the operation of the entire machine, that can achieve automatic running. Each part is equipped with a detection switch to detect the operation of the equipment in real-time.

If you are also interested in our machines, please feel free to contact us WhatsApp: 0086 131 8895 5372. We will recommend the most suitable machines depending on your processing needs and provide you with the most comprehensive and high-quality services.