The machine

Stone shot blasting machines for the superficial treatment (roughening, glazing, distressing) of pavers, concrete blocks marble tiles, slabs of natural marble or agglomerate, granite, as well as cement tiles, interlocking paving, kerb-stones, etc.

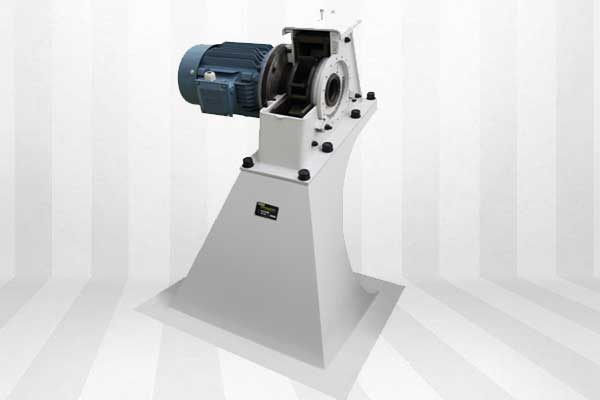

Pieces are transported on a horizonta conveyor belt; the blasting effect is obtained through the centrifugal projection (without compressed air) of spherical steel shot.

The parts to be treated will be placed on the network in the entrance area manually or with automated systems then introduced into the blasting cabin where a series of turbines, appropriately positioned to the section of passage pieces, provides the projection of metal abrasive on the surfaces to be cleaned.

It is possible to vary the speed of transportation or of shot projection, according to the effect desired or to the hardness of the surfaces to be treated.

Features and benefits

-The adjustable blast wheels provide a very uniform surface result, even at high speeds

-This is assured by smooth/stepless speed control, electro-pneumatic dosage regulation and optimal blast wheel positioning

-PLC control system, stable quality and easy to get support from local.

-Auto-detection, auto-alarm and auto-cutout. Alarm system adopts audible and visual alarm.

-Setup safety interlock device between systems

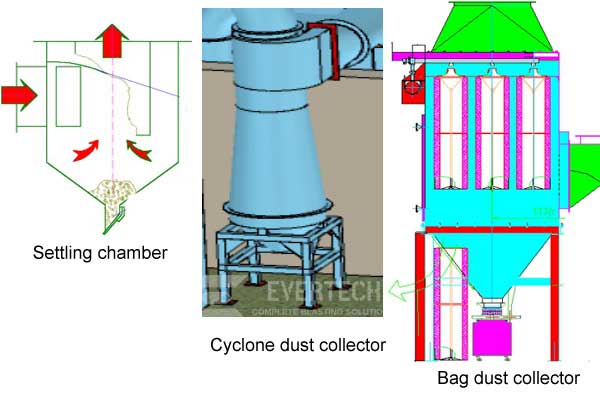

-Dust collector with Pulse-jet cleaning bag filter to remove dust

-Component key parts adopt world famous brand, such as Siemens, Omron, Schneider, Mitsubishi.

-Can be designed and manufactured according to the order.

-Easy operation

-High operational safety

-Easy integration into existing production lines

-20 years experienced engineers, customized service avaliable.

Applications

Surface texturing of concrete products like:

-Blocks

-Slabs

-Kerbstones

-Pavers

Conveying system

-Rubber belt

-Roller conveyor

-Wire mesh belt

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews