The machine

The Indexing Hanger Shot Blasting Machines are particularly suitable for the surface treatment and deburring of aluminium parts, descaling of forgings and desanding of castings, especially when dealing with workpieces whose shape or size makes them ill suited to tumbling.

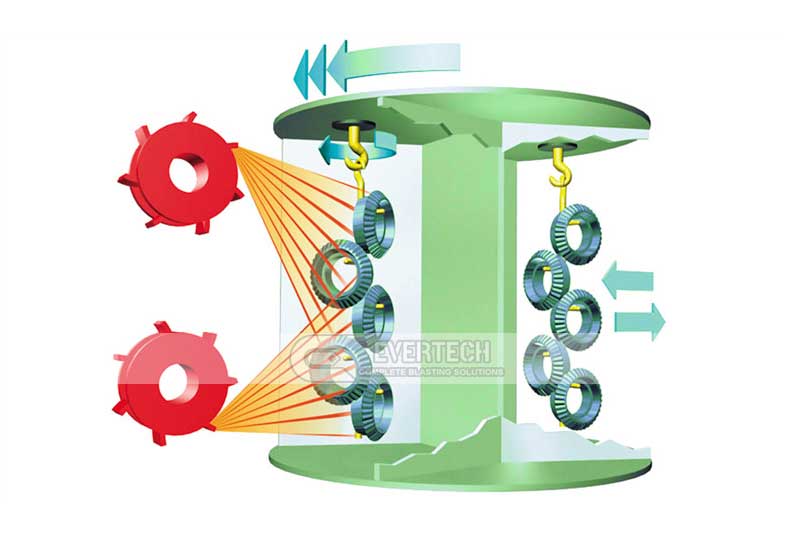

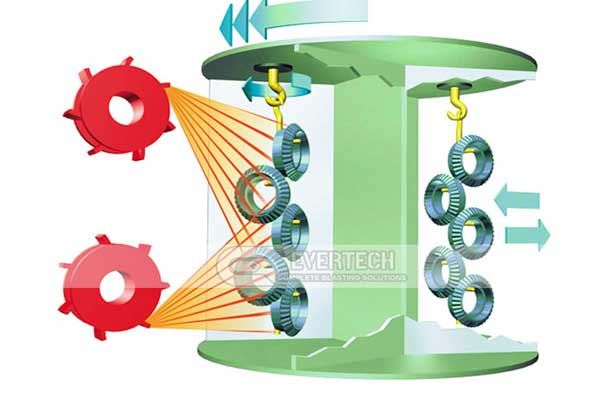

The indexing hanger shot blasting systems do not require any foundation and mainly comprise an enclosure housing the vertical rotary chamber, which is divided into two compartments: the sandblasting unit with blast wheels and the abrasive separation unit.

Each compartment features a rotating hook accommodating stands on which the parts to be cleaned are positioned. The machine’s unloading area is open, thus allowing for loading and unloading while parts are undergoing sandblasting in other compartments.

Every time the chamber indexes to its next position, the abrasive stream delivered by the blast wheels is stopped until the table has finished turning. The hook, which rotates continuously, ensures full blast coverage of the part so that there are no blast shadows the abrasive stream is unable to reach.

Applications

-Desanding, decoring and surface finishing of iron, steel and light metal castings, including parts susceptible to breakage and impact damage

-Descaling of forgings, hardened or heat treated steel parts

-Surface preparation before coating or other applications

-Best suitable for aerospace and automotive industries

-Used for shot peening of several components like gear shafts, axles, big gears, crankshafts, etc.

-Cleaning and peening applications

Features and benefits

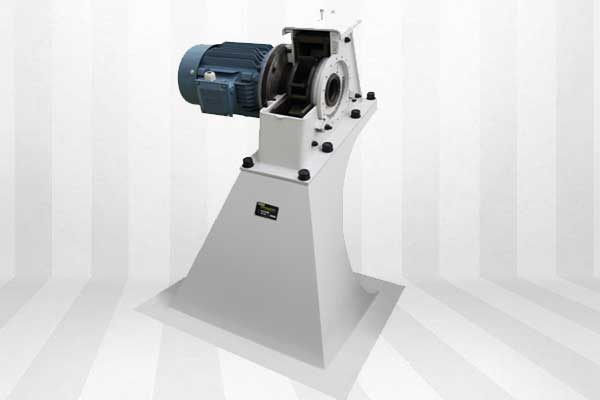

-MARSH - High Wear Life Carbide Alloy Parts

-MARSH - High Performance Blast Wheels.

-Complete Mn. Steel Construction

-Robust Mn. Steel blast wheel housings.

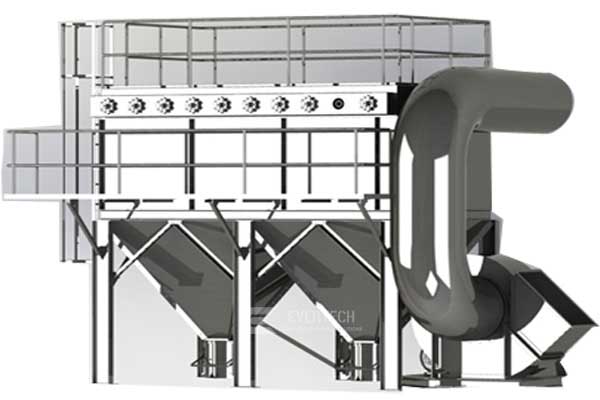

-Efficient abrasive recycling system.

-Extreme low maintenance machine

-High Efficiency Dust Collectors

-All critical wear pats manufactured from special carbide alloy or tool steel

-Fool-proof and intelligent machine control system.

-Range of blast wheels offered.

-Speed batch blasting of sensitive parts

-Deliver 360° workpiece coverage

-Continue working during loading

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews