The machine

This kind of tumble shot peening machines are the most cost-effective solutions, it is suitable for the company which not high production capacity, complete strengthening effect for springs in batches.

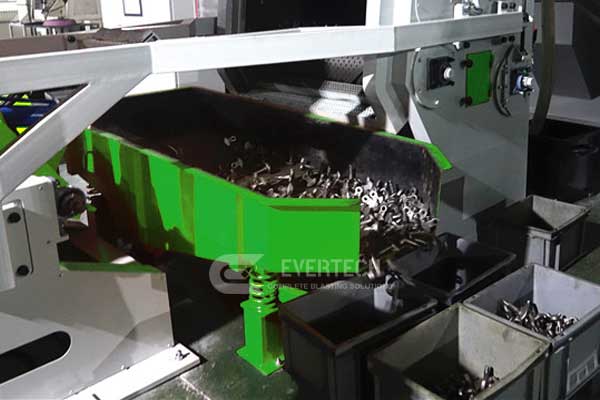

Tumblast with steel belt conveyor are suitable for the treatment of pieces in quanitity, having unit weights that can vary from few hundred grams up to 250 kg, depending on the shot blasting machine type. The maximum loading weight varies from 600 to 3.000 Kg. The work-pieces placed loosely on the endless turning on belt and they are shot blasted by the wheels positioned on the roof of the machine.

Applications

-Cast parts in brass, cast iron, steel and aluminum

-Pressed parts in steel or brass

-Forged parts

-Heat-treated parts

-Springs

-Various mechanical parts. etc.

Features and benefits

-Our tumble belt blast machine are designed to process a variety of parts that can be tumbled.

-The endless conveyor belt and lateral round place creates a trough in which parts are treated.

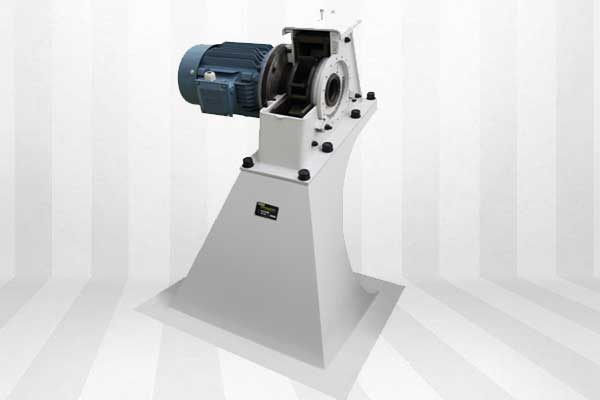

-The number and power of the turbines are chosen according to the requirement production rate.

-Optional PLC control system, stable quality and easy to get support from local.

-Component key parts adopt world famous brand, such as Siemens, Omron, Schneider, Mitsubishi.

-No-pit, easy for install and move and save cost.

-A high volume of parts can be processed in a small working area.

-All shot blasting machines are totally integrated with abrasive reclaim systems, separator and dust collector.

-Superior design, quality and rugged construction make our barrel machines more reliable and easier to maintain.

A hydraulic skip loads the machines whilst unloading can be done directly into the container, or on a vibrating channel that allows the recovery of the shot remaining on the work-pieces.

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews