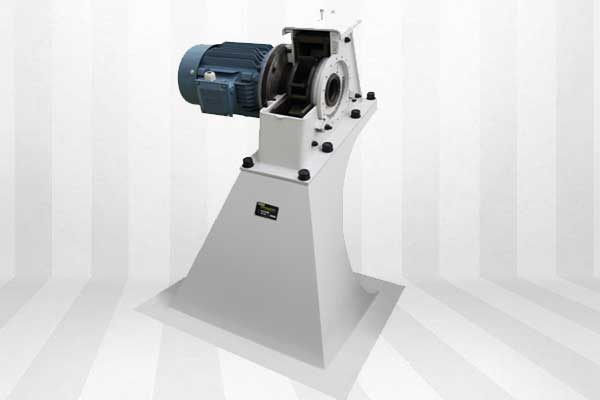

The machine

Wire mesh belt shot blasting machine excellent for all-round, complete and continuous blasting treatment of flat as well as voluminous and very complex components.

Wire Mesh Belt shot blast systems are designed to provide a high throughput for a variety of product sizes and shapes. This proven continuous in-line shot blast cleaning system is available in standard and custom Designs. This system is ideal for deburring, general cleaning, descaling and deflashing and is equipped with 2- 16 shot blast wheels, processing widths ranging from 400 mm to 1600 mm, depending on your cleaning and production requirements. Wire Mesh Belt blasting equipment is installed to reduce operating costs since the blast cleaning process can be easily integrated into a production line, for fully automatic product flow.

Applications

-Foundry Castings

-Forgings

-Die Casting

-Heat Treated Parts

-Aluminum Alloy Castings

-Weldments

-Fabrications

-Automotive Parts

Features and benefits

-Uniform blast cleaning effect, perfectly clean castings

-Adjustable blasting intensity to suit different types of castings

-In-line operation, continuous blast cleaning

-Clearly arranged manufacturing sequences

-Improved manufacturing consistency

-Short transport distances (no intermediate storage)

-Reduced operating costs

-The machine consist of „ready-to-operate“ modules which can easily be transported and mounted

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews