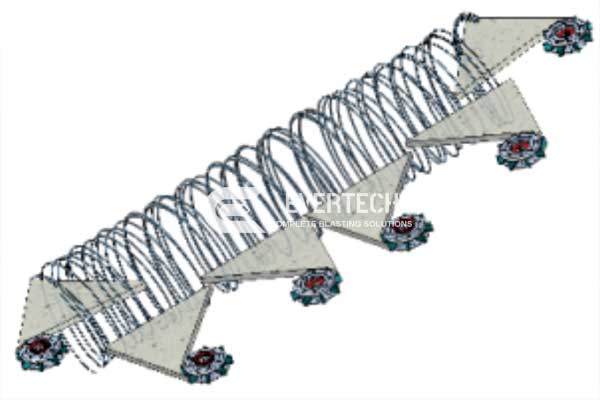

Wire rod, Bar, Billets Shot Blasting Machine

Position: Home > Wire rod, Bar, Billets Shot Blasting Machine > Wire Coil Shot Blasting MachineWire Coil Shot Blasting Machine

The wire coil blasting machine has been designed to process wire rods of up to 3000kg of weight at a time ranging from 7 to 20 minutes.

| Model | Type ETC |

| Price | Negotiation |

| Rating |  4.0 /5 based on 28 ratings and reviews 4.0 /5 based on 28 ratings and reviews |

| Operation Method | Automatic |

| Brand name | Evertech |

| Place of Origin | Qingdao, China |

| Certification | CE, ISO, UL |

| Process | Batch |

| Industry | Light/Medium |

| Delivery Time | Within 15 weeks |