Container Sandblasting Room

Position: Home > Container Sandblasting Room > Side Door Open Containerized Grit Blaster | 20ft Containerized Sandblasting RoomsSide Door Open Containerized Grit Blaster | 20ft Containerized Sandblasting Rooms

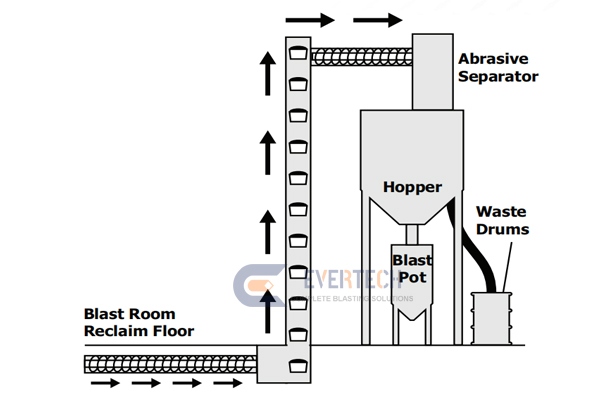

The customized side door open containerized grit blaster , which is more convenient and simple to load and unload large workpieces....

| Model | Type ETBR |

| Price | Negotiation |

| Rating |  4.0 /5 based on 28 ratings and reviews 4.0 /5 based on 28 ratings and reviews |

| Operation Method | Automatic |

| Brand name | Evertech |

| Place of Origin | Qingdao, China |

| Certification | CE, ISO, UL |

| Process | Batch |

| Industry | Light/Medium |

| Delivery Time | Within 5 weeks |