Container blasting room

Evertech design and manufacture a complete range of standard and custom built blast cleaning rooms and enclosures.

With a standard range of containerised blasting rooms in 20 or 40ft, or the option of self-build packages, any size component can be catered for.

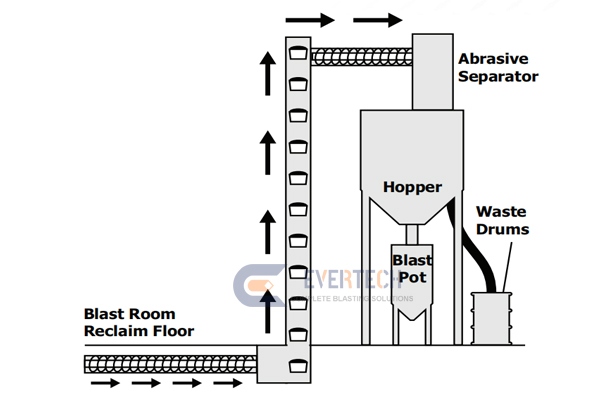

A wide selection of abrasive recovery floors and dust collection systems are available to suit any size room. Sweep in systems powered by compressed air are available off the shelf with built in abrasive cleaning and capacities of 2 or 4 tonnes per hour recovery rates.

Fully automatic floors with Scraper conveyers, bucket elevators, and storage hoppers can be supplied to customer specifications or customised in self-assembly kits with drawings.

Container blasting room fitted out with

-20' or 40' shipping container (modified)

-Container doors on one end

-Galvanized steel plate on floor

-LED lighting

-Shovel-in hopper, bucket elevator and air wash

-Abrasive storage hopper

-Sandblasting pot

-PPE for one operator

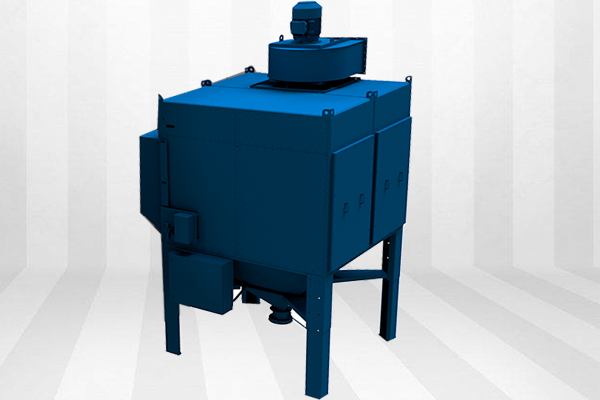

-Cartridge filters dust collector

-Electric control panel

-Rubber sheeting on walls

-Air inlet and air exhaust plenums for dust collection air

*full floor recover system is available as an option*

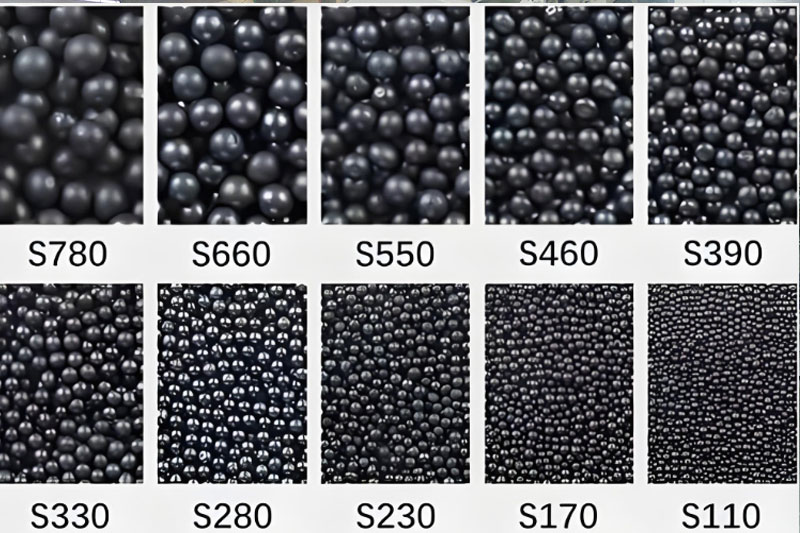

Suitable for a wide range of abrasive media including but not limited to

-Steel shot

-Steel grit

-Chilled iron

-Aluminium oxide

-Glass bead

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews