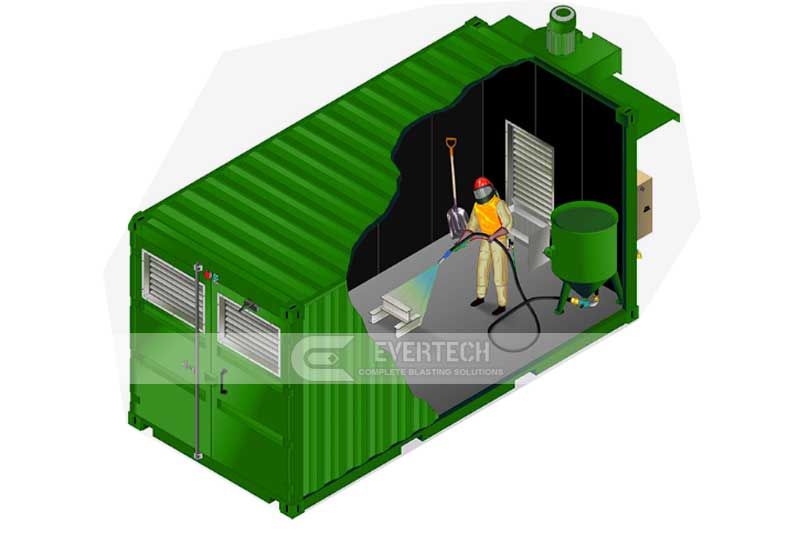

Mobile / Transportable Container Blasting Room

Evertech containerized blast rooms are made from converted shipping containers, which provide an economical solution when a weatherproof and/or transportable blast room is required. This versatile, mass-manufactured, watertight enclosure is an ideal starting point for a blast room, particularly when it may be relocated at some point or if it is to be situated outside in the elements. Evertech re-engineers standard shipping containers to incorporate many of the same features found in our modular blast rooms. These include well designed ventilation systems, rubber curtains, purpose built light fixtures and advanced controls. Our containerized blast rooms may also be fitted with any of our media reclamation systems.

So if you need some heavy-duty space for shotblasting work, you could do a lot worse than start with a shipping container. They’re easy to get access to, they don’t cost an arm and a leg, and they can be customised to fit your personal needs. Converting a container is one of the best methods that you can find for temporary or small-scale blastroom operations.

We also carry out investments together with the client where the client provides the container on his own and we equip them with the necessary installations.

Compact solution

This innovative cartridge filter module comes pre-installed inside each All-In-One Containerized Blast Booth – no extra ducting is required. Commissioning and calibration are also taken care of in our factory before shipping, so your blast room arrives ready to go; simply hook up the power and air supplies and start blasting.

Blast room fitted out with

-Main doors suitable interlocked – to prevent blasting with doors open.

-Operator door – as a means of exit if main doors are stuck, also interlocked.

-LED lighting.

-Emergency lighting.

-Steel floor with side shedders.

-Cross screw conveyor at the bulkhead.

-Air inlets providing ventilation for blast room and good operator visibility.

-Shot-blast quality rubber lining of room.

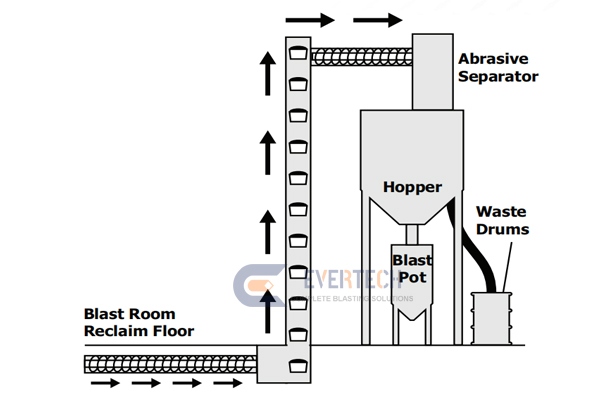

Service room fitted out with

-Lockable access door

-Abrasive elevator

-Abrasive airwash unit

-Blast pot with control equipment

-Breathing air filter for operator

-Dust extractor

-Electrical control equipment

-LED lighting

-Externally mounted silencer

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews