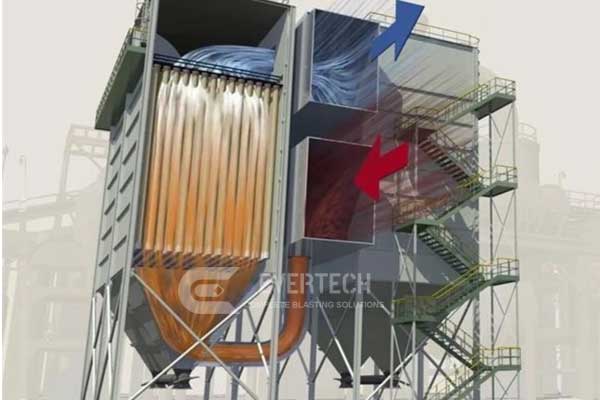

The filter bags dust collector

The dust-laden airflow enters the ash collecting hopper through the air duct, and part of the coarse particle dust falls into it by inertia. The remaining exhaust gas dust is filtered by the filter bag and enters the upper box, and then is discharged into the atmosphere by the induced draft fan through the exhaust duct.

After the dust collector runs for a period of time, the dust layer collected on the outer surface of the cloth bag thickens, and the running resistance of the dust collector rises. When a certain value is increased, it is necessary to clean the cloth bag, that is, to remove the dust on the outer surface of the cloth bag through external force. The dust is removed. The entire dust removal process is mainly carried out by compressed air. When the resistance rises and dust removal is required, the controller opens the pulse valve through instructions, and the cloth bag deforms under the action of the compressed air, so that it can remove the dust attached to the outer surface of the cloth bag. purpose.

Features and benefits

-Adopt high-efficiency and low-consumption injection device to realize low-pressure, short-pulse injection, online dust removal, and improve dust removal intensity.

-Reasonable airflow organization, adopting downstream airflow and downstream filtering, so that the dust has the effect of cohesion and sedimentation at the same time in the filtering state, reducing the bag load and blowing frequency.

-The mouth of the filter bag is sealed with an elastic expansion ring, which has good tightness and is convenient for disassembly and assembly.

-The filter bag frame adopts resistance welding, and the appearance is smooth without welding marks, which solves the phenomenon of wear of the filter bag and the frame, and the filter bag has a long service life.

-The injection pipe is equipped with different short pipes according to different positions to ensure that each filter bag is evenly cleaned and prevents deviation and filter bag damage.

- Using "microporous membrane composite filter material", the dust removal efficiency is >99.9%, suitable for dust removal of high humidity dust-containing gas.

-Adopt pulse jet method of dust removal. It has the advantages of good dust removal effect, high purification efficiency, large processing gas volume, long filter bag life, small maintenance workload, safe and reliable operation, etc.

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews