The machine

Steel shot blaster is a machine suited for medium to large steel blasting projects. This machine is capable of preparing steel surfaces such as petrochemical or water storage tank floors and roofs, ship decks, barges and other marine vessels, hatch covers, bridge decks and offshore drilling platforms. The steel shot blaster utilizes a center fed blast wheel design to propel steel shot, hardened steel grit or a mixture of both, to the surface allowing the operator to achieve a wide range of surface profiles as specified.

Applications

-Tank floors

-Roofs and steel plates

-Ship decks

-Hatch covers

-Barges and other marine vessels

-Bridges decks

-Walkway’s on offshoredrilling platforms

-steel pipes

-Inside of the tanks

Features and benefits

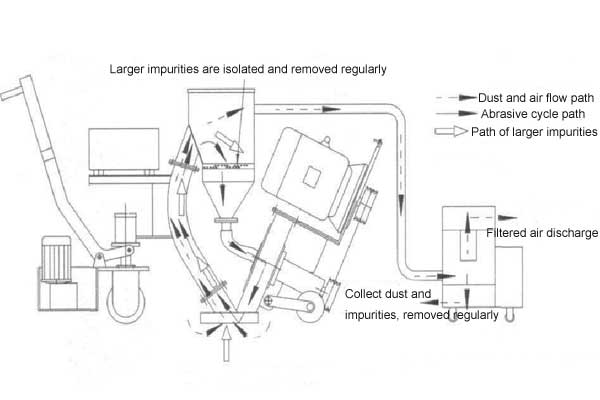

-Closed circuit which is dust free, when connected to an appropriate dust collector.

-Increased productivity, reduced maintenance costs.

-Fast and efficient removal of coatings, paint, rust and mill scale.

-Ergonomic design and user friendly control panel.

-Grill fitted into lower separator hopper unit assembly to eliminate foreign objects being allowed into the blast wheel and causing damage

-High build quality to ensure long lasting components

4.0 /5 based on 28 ratings and reviews

4.0 /5 based on 28 ratings and reviews